Industrial Automation And Control News

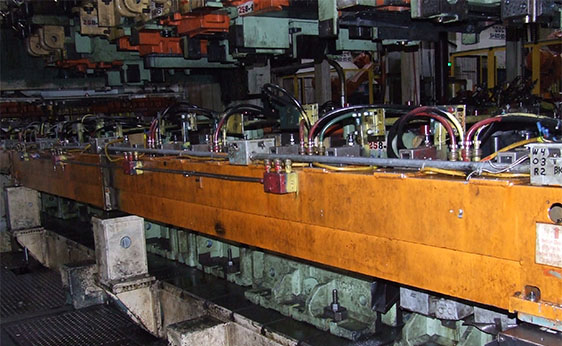

In the industrial stamping industry, press & transfers and the surrounding automation are some of the most crucial components of the manufacturing system, so bringing them down for any length of time, be it for for replacement, scheduled maintenance, or necessary upgrades, has a huge impact on production. With so much at stake riding on the rails of the transfer, it is no wonder many companies are so reluctant to upgrade and are instead relying on hardware and software that is over 20 years old.

With experience retrofitting and upgrading over 30 presses, as well as transfers, feeders, destackers, and main motors, Brave has earned a reputation for achieving automation excellence in the stamping industry for our ability to deliver complicated upgrades smoothly and successfully.

Brave has provided turnkey solutions for industrial transfer press systems while handling all aspects from project management, electrical design, software development, supplying of panels and field materials, electrical install support, site project coordination, start-up commissioning and production support.

4 Transfer Press Refits completed 2013-2015

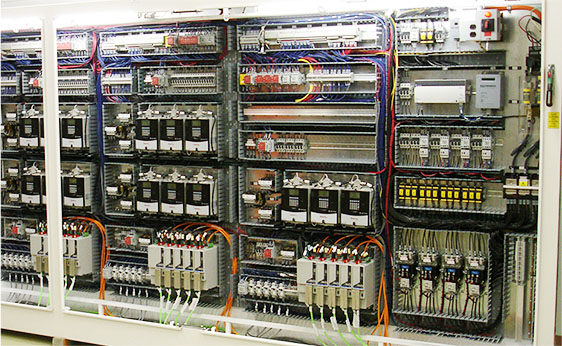

Provided a turnkey solution to replace existing SquareD controls to Siemens

2x Verson Single Slide

1x Danly Single Slide

1x Komatsu Double Slide

2 Transfer Press Refits completed 2015-2017

Provided a turnkey solution to replace existing PLC5 controls to GuardLogix

2x IHI Triple Slide

Transfer upgrades and integrations require a company with the experience to handle the pressure these high stakes, high risk projects entail. Brave is experienced and equipped to lead you through all aspects of your transfer upgrade or integration, from project management, electrical design, software development, supplying of panels and field materials, electrical install support, site project coordination, start-up commissioning through to production support.

3 Transfer Refits completed 2013-2015

Provided a turnkey solution to replace existing Unico ETF controls to Siemens

2 Transfer Integrations completed 2013-2017

Provided a turnkey solution for the integration of new ETF into existing press controls.

4 Destacker to Press Automation completed 2015-2018

Successfully integrated brand new Siemens controlled gantry into Rockwell PLC

Project Management, Software Development, Commissioning and Support

5 Transfer Press End of Line Integrations completed 2013-2016

3x Turnkey Press EOL Controls Refit SqaureD to Siemens

2x New EOL Systems with Siemens controls

2 Transfer Press End of Line Integrations completed 2016-2017

2x Turnkey Press EOL Controls Refit from PLC5 to ControlLogix

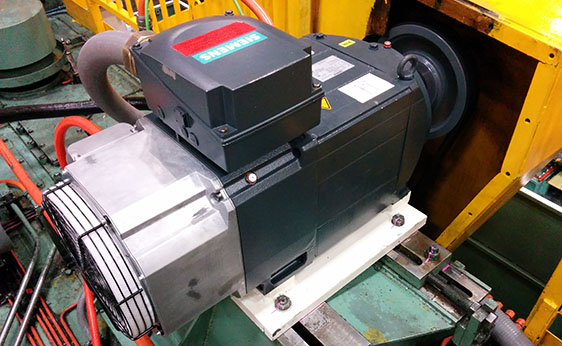

Brave has completed numerous main motor refits and integrations for customers over the years. By working closely with our partners and customers we are able to seamlessly swap obsolete AC motors and drives with newer, low cost DC motors while working within scheduled downtime with virtually no changes for the operators.

4 Main Motor Integration with New Controls completed 2013-2015

Provided a turnkey solution for the integration of new main motor drive and motor into brand new Siemens press controls.

2x Verson Single Slide

1x Danly Single Slide

1x Komatsu Double Slide

8 Main Motor Integration with Existing Controls completed 2013-2017

Provided a turnkey solution for the integration of new main motor drive and motor into existing new press controls.

3x integrating into SquareD PLCs with hardwired interface

5x integrating into Modicon PLCs with MB+ interface